Mor Temor

Arch. Mor Temor is international Architecture firm committed to designing unique buildings and one of a kind architectural concepts.

2.29 Floating Inhabited Bridge

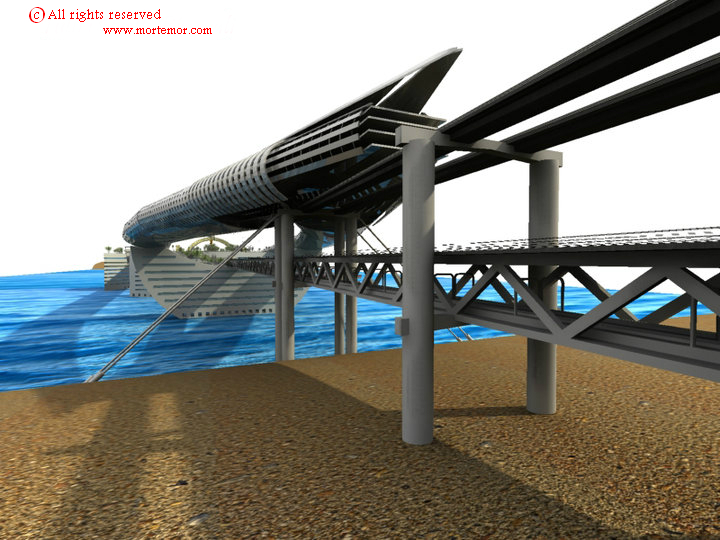

The ordinary bridges and tunnels (underground and submerged) were investigated and assessed for bridging Messina Strait. For years there have been several detailed investigations on this subject by researchers all over the world. We can conclude from the comparative study that those ordinary structures would be difficult or economically infeasible; instead, to make truly bridge anywhere near economically feasible, change in ordinary bridges typologies are required: A bridge with ‘Living Floating Platforms’ would be proposed to be adopted as the first of this kind in the world.

The proposed Floating Bridge consists of revolutionary type of cable stayed bridges coupled with use of mega concrete floating inhabited units foundations. This system is a true pioneering development in bridge architecture and engineer; from an aesthetic point of view the system have a new pleasing shape and from engineering point of view a truly stabile Floating Cable-stayed Bridge of huge dimensions has been proposed across strait (see Fig.66);

Fig. 66 Floating Inhabited Bridge over Messina Strait.

Structural, Architectural, Environmental and economic characteristics

Here, an overview of long study on the design and analysis of the proposed Messina Straits Floating Bridge in Italy (new generation); basically, it is the result of laborious research on floating structures and living bridges techniques that have been proposed by designers and engineers, these aspects include architectural design, structural concepts, mooring systems, environmental impact and economic benefit;

The main characteristics:

a) It uses water as foundation for the bridge decks and pylons. The proposed configuration rests on huge concrete floating inhabited units foundations that would be used as a support of commerce, work spaces, parks and transportation, generating more than 3,000,000 m² of built space assets within the two steel Living Decks that would be used also as a support of built habitable volumes of dwelling and transportation (see Fig. 67).

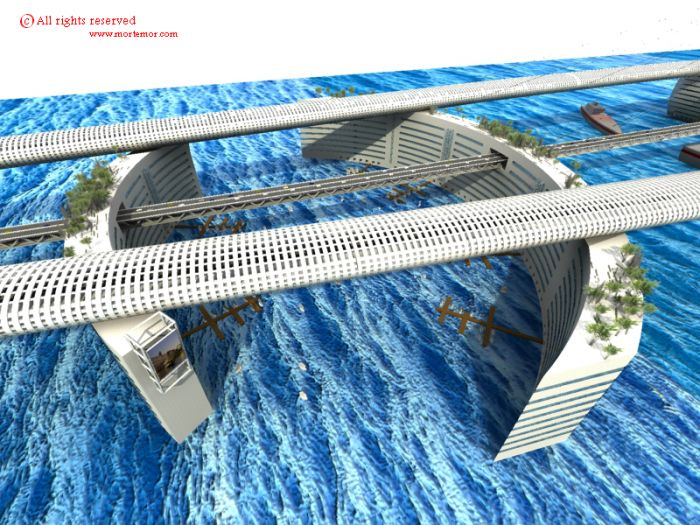

Fig. 67 Huge concrete floating inhabited unit foundations located in the middle of the Messina Strait to enable the passage of large ships.

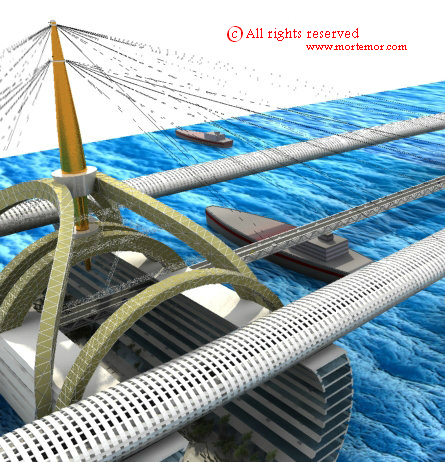

The floating structures which support the pylon of the cable stayed bridge would be located in the middle of the crossing to enable the passage of large ships. These floating structures have a cylinder shape and two arcs supporting the pylon; thanks to this shape and to these arcs that the interior stress forces can distribute basically in compression stress and all the structure is more stable.

A cable stayed-bridge concept is chosen because it is an ideal field for creativeness in design to satisfy the functional requirements of the project and to obtain an aesthetically pleasing structure which complements the environment, i.e. special situations such as: the curved spans of the Living Decks can be easily solved using stays, the combination of the pylon with two arcs and six inclined cable planes will give a minor deformational effect under eccentric loads (traffic, ecc.). Furthermore, a cable stayed-bridge is much more economical, stiffer and aerodynamically safer than a comparative suspension bridge.

The combination of cable stayed and floating structure open to new concepts, ideas and design that technically and economically improve the Bridges over Straits. The proposed floating structure would be approximately 65 m high from water surface with a span length at least 500 m in the middle for ship save crossing. This revolutionary configuration represents a new dimension in Floating Bridge; this will be the first time that a truly stabile Floating Bridge in order to provide the non interruption vehicular traffic and non interruption navigation channel for Ships with more than 50.000 Dead Weight Tonnage. Thanks to this revolutionary configuration no more necessary fixed suspension bridges or movable spans to enable the passage of large ships.

b) However for an articulated structure as in this project the resulting bending moments and torsion would be unacceptably high. Therefore pretensioned vertical tendons (TLP), or tension legs or tethers, in combination with two horizontal curved steel ellipse-net structure (see Fig. 68-69) appear to be the best choice of mooring system for the floating units. The tethers are pretensioned by the excess buoyancy provided by these units and the restoring forces in the horizontal plane for the inter structure are provided by the two horizontal curved steel ellipse-net structure with the radius of curvature at least of 1000 m.

Fig. 68 The two horizontal curved steel ellipse-net structure.

Fig. 69 The pretensioned vertical tendons (TLP).

The use of steel-net members is also very effective since it acts as either an arch rib, that is structurally much stiffer than a girder of the same cross-section when the current is coming from its convex side, or as a similarly effective catenary cable, even when the current is reversed; the inter structure is designed to be strong and stable enough to withstand typhoon-level wind and waves.

This combination represents a new dimension in Floating Bridge; this will be the first time that a truly stabile Floating Cable-stayed Bridge of these dimensions has been proposed across seawater; a main advantage with this system is that it will be easy to design the system such that slack of leeward mooring lines are avoided. Thanks to this new combination no possible slack could be followed by a sudden increase in tension that involves dynamic amplification and possible failure.

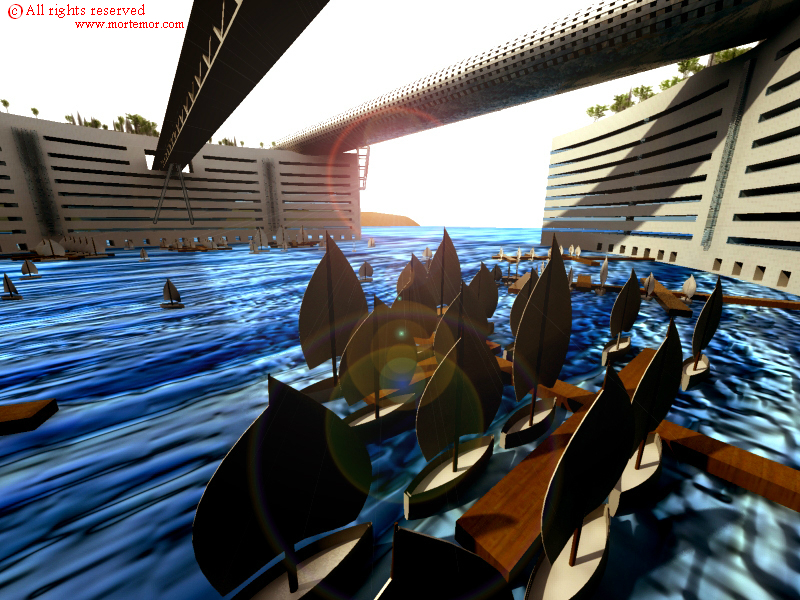

c) Even though it still in the planning stage, the Living Deck (ellipse-net members) will surely be one of the most exciting construction projects in the next few years: At ~3300 meters long, ~60 meters wide, panoramic views across the seawater for pedestrians, the dense atmosphere of a greened urban pedestrian zone sheltered from the wind, the habitable deck would be basically of steel and glass. The lowest level would be a course similar to a street, above that there is a six stories that would accommodate a total of approximately 8,000 flats. This deck, with a central span at least 500 m, and a deck height of ~30 m, represents the generation of the up-to date bridges with aerodynamic box deck (second generation of suspension bridges). This kind of deck was conceived as a structure with aerodynamic profile, which holds good transversal stiffness thanks to the ellipse-net configuration, but it is more effective than the truss girder deck to face wind action; due to the large torsional stiffness and the streamlined shape of the ellipse-net oscillations would be eliminated completely for actual wind speeds.

The steel Living Deck represents a new dimension in Living bridge-building (see Fig. 70). This will be the first time that a truly urban, bustling pedestrian-friendly Living Bridge of these dimensions including green areas has been proposed across seawater; which is itself not just a road bridge but also an inhabited, lively city.

Fig. 70 The steel Living Deck

d) A floating foundations unit is chosen because of water depth more than 80 mand bedrock lies more than 250-m below the seabed, which makes conventional piled structure extremely expensive. Another reason for choosing floating foundations units is the seismic hazards dictated by proximity to the Etna volcanoes; It is earthquake resistant, floating structures are inherently base isolated from earthquakes, they are ideal in earthquake prone countries.

e) The change in water level due to tide, tsunami and storm was taken into consideration, because the structure is designed with a fixed vertical position relative to the seafloor (TLP), any change in water level cause the floating structure would be subjected to additional large stresses. For this reason in the design details introduce the so-called gill cells which are compartments within the floating structure with holes or slits at the side face to allow water to flow in and out freely. These gill cells reduce the stresses while maintaining the structural stiffness integrity (see Fig. 71).

Fig. 71 On the level of the water present the "gill cells", to allow water to flow in and out freely.

f) During the design of the main road and railway deck, it was reused the proven typology of the ØresundBridge[1]; The deck would has two vertical main trusses positioned immediately outside the clearance profile of the railway tracks on the lower deck (see Fig. 72). With this layout would not only ensure that the heavy train load should be carried a minimum distance transversally to the main trusses but also that the upper roadway deck would be efficiently supported with a reasonable ratio between the intermediate span above the railway tracks and the overhangs outside the main trusses. This would be possible to make the roadway deck with its total width of 23.5 m as a hunched and prestressed concrete slab supported directly on the top chords of the main trusses.

This deck (with a central span at least 500 m, and a deck height of ~11 m) represents the bridge generation with truss deck conceived as stiffening girder (first generation of suspension bridges), designed to face wind action and other stresses with strong inertia that, on the other hand, produces strong aerodynamic resistance.

Fig. 72 The deck with two vertical main trusses positioned immediately outside the clearance profile of the railway tracks on the lower deck.

g) The proposed solution, applying a concrete Floating Foundation-Inhabitant Units, it can be economically constructed in a shipyard and floated two or more standardized modules at a time comprising spans, pylons and foundation units to the designated water crossing, erected and finished on site. So the construction is very timesaving and cost-effectiveness.

h) The construction of the Bridge is expected to cost approximately 10 Billion USD and requires some two years to complete. With the sale of the inhabitant units, more than 3,000,000 m²of built space, is sufficient to reach sufficient financial budget, which confirms the financial feasibility of the project.

i) The proposed concepts consist of applying existing offshore technology and structural concepts to the problem, since the main technological challenges have already been resolved by the offshore oil and gas industry (see article 2.24).

j) Environmental impact of the proposed floating bridge construction is far less than by other methods; land reclamation in ocean space saving the ecological condition and natural reserve of the site.

k) Electric energy production using the currents of the Strait. The turbines would be installed on the seven floating elements, on the submerged parts, at 20 to 30 metersdepth.

Photovoltaic colored solutions can also be integrated perfectly into the Floating Bridge, provide greater both acoustic and thermal insulation and at the same time produce clean, free energy in situ, all thanks to the power of the sun.

l) The Living Floating Bridge will provide Messina Strait with a landmark like the Ponte Vecchio in Florence or the Rialto Bridge over the Grand Canal in Vinice.

Arch. Mor Temor

[1] The longest of all cable-stayed bridge carrying both road and rail way traffic built in 1996 between Denmark and Sweden. The bridge has a total length of 7,8 km and out of this length the cable-stayed portion at the navigation channel constitutes approximately 500 m.